close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-09-12 Origin: Site

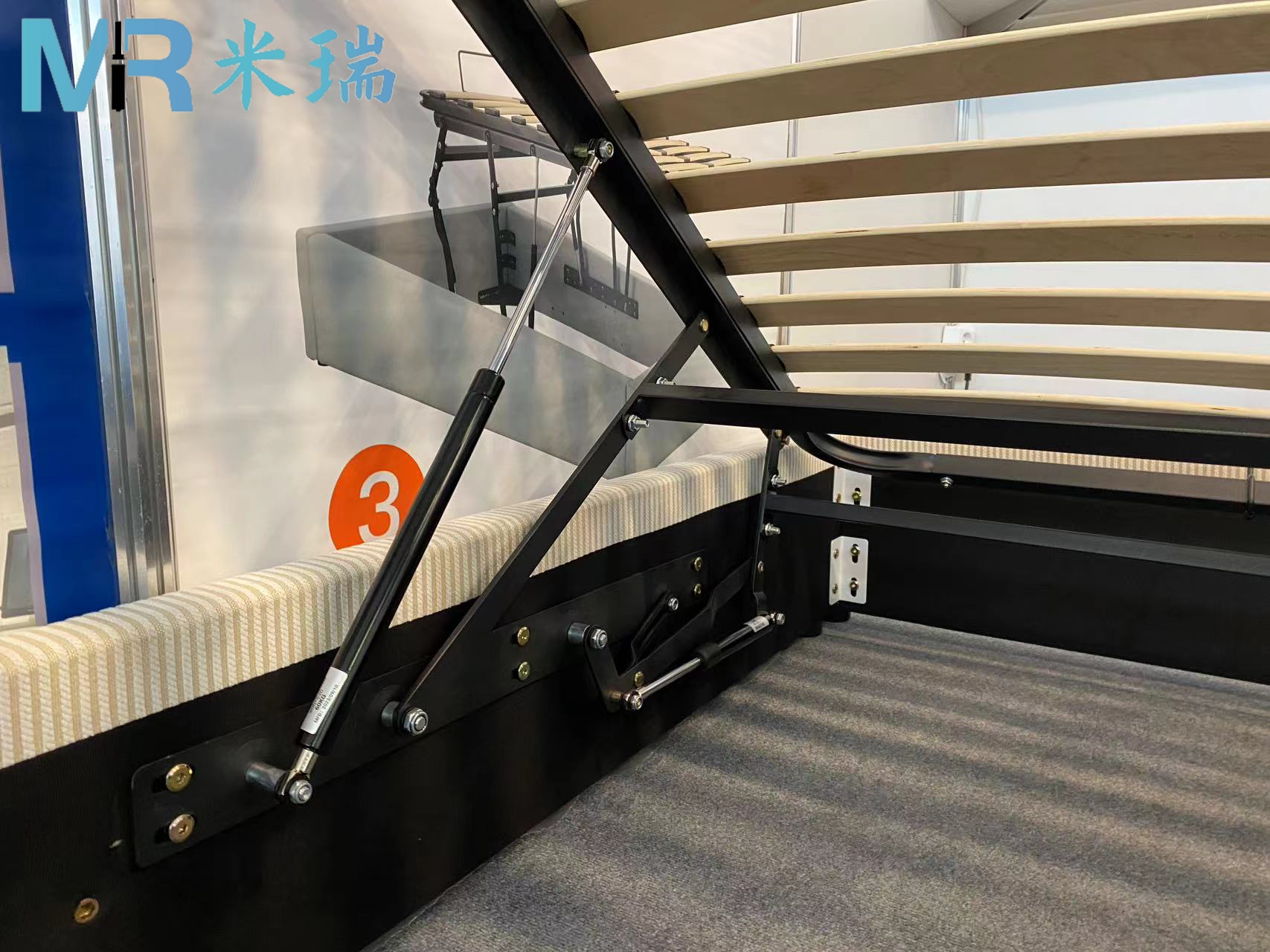

Gas springs, also known as gas struts, are essential components in various industries, from automotive to medical and furniture applications. They store energy by compressing gas within a sealed cylinder, which is then released to assist in controlled movement. This article will explore the purpose of gas springs, their benefits, types, applications, and how to choose the right one for your needs. We'll dive into how these remarkable devices function, their common uses, and answer frequently asked questions about their role in mechanical systems.

A gas spring is a type of spring that uses compressed gas, usually nitrogen, within a sealed cylinder. The basic structure consists of a cylinder, piston, and rod, which work together to create controlled movement when force is applied. Unlike mechanical springs, which rely on elastic deformation to store energy, gas springs store energy in the form of compressed gas and lubricating oil inside the cylinder. When the gas is compressed, it creates increased pressure that pushes the piston, and when the pressure is released, the gas expands to return the piston to its original position.

This mechanism allows gas springs to provide smooth and controlled movement with adjustable force, making them highly versatile in a wide range of applications. Gas springs struts are specifically designed to support or assist the movement of various components in different systems, offering a more durable, reliable, and efficient solution compared to traditional mechanical springs.

The operation of a gas spring is fairly straightforward. The gas inside the cylinder is compressed by a piston that is moved when an external force is applied. The compressed gas creates pressure that pushes against the piston, causing it to move and releasing the stored energy. This controlled movement helps to reduce the effort needed to lift or hold heavy objects, providing an efficient solution for many mechanical applications.

The gas spring calculator is a tool used to determine the appropriate gas spring based on the specific application’s requirements, including the force needed, stroke length, and mounting options. By adjusting the pressure and the size of the cylinder, the springlift gas springs can be customized to suit the exact needs of any system.

There are several types of gas springs designed for various applications. Below are the most common types:

Fixed Gas Springs: These gas springs are pre-loaded with a set amount of gas pressure, making them ideal for applications where a constant force is required. Fixed gas springs struts are used in systems where the force required is predetermined, such as in office chairs, cabinet doors, and automotive hoods.

Traction Gas Springs: Unlike traditional gas springs, which provide pushing force, traction gas springs provide a pulling force. The piston rod is in a relaxed position inside the cylinder, and the cylinder pulls the rod back, making it perfect for applications where objects need to be raised or pulled in a controlled manner, such as in automotive doors or windows.

Pressure Adjustable Gas Struts: These gas springs allow for customizable force settings. By adjusting the internal pressure, you can modify the force applied by the gas spring, making them versatile for applications where the required force is not fixed, such as in medical equipment or heavy machinery.

Lockable Gas Springs: Lockable gas struts provide an additional feature where the piston rod can be locked at a specific position. This locking mechanism ensures that the object remains in place until manually released, which is essential for heavy-duty applications where objects need to stay in a fixed position under considerable forces, like in construction machinery.

Gas springs are used in a wide array of industries, including automotive, furniture, medical, and industrial sectors. Here are some of the most common uses:

Automotive Industry: Gas springs are widely used in vehicles to assist in opening and closing hoods, trunks, and doors. They help in reducing the effort required to lift and support heavy components, providing smooth motion and ensuring safety when handling automotive parts.

Furniture Industry: Adjustable office chairs, recliners, and height-adjustable desks rely on gas springs to provide smooth and controlled movement. They allow users to adjust the height of chairs or the tilt of seats, improving comfort and ergonomics in furniture design.

Industrial and Aerospace Uses: In industrial applications, gas springs help in lifting and supporting heavy loads. They are used in machinery, presses, and other equipment to assist in the controlled movement of components. Gas springs are also essential in aerospace applications, such as controlling the movement of airplane doors and hatches.

Medical Equipment: Hospital beds, adjustable examination tables, and other medical devices often use gas struts for smooth and adjustable motion, providing comfort and ease of use for both patients and medical staff.

Marine Industry: Gas springs assist with the movement of hatches, cabinets, and storage compartments in marine applications, providing controlled motion that can handle the harsh marine environment.

Gas springs are incredibly versatile and can be found in numerous other applications:

Home Appliances: Gas springs can be used in kitchen cabinets, washing machine lids, and other household appliances where controlled lifting and support are required.

Gym Equipment: Many types of gym equipment use gas springs to provide smooth and adjustable movement, such as adjustable weight benches or resistance machines.

Recreational Equipment: Items such as RVs, bicycles, and boats use gas springs to assist in adjusting seats, hatches, and other components.

Gas springs offer several advantages over traditional mechanical springs, including:

Durability: Gas springs are made from high-strength materials and are less susceptible to wear and tear compared to mechanical springs. This makes them ideal for applications that require long-term reliability.

Safety: Unlike traditional mechanical springs that can fail suddenly and cause damage, gas springs provide a controlled release of energy, reducing the risk of injury or equipment damage. Safety mechanisms, such as over-stroke and over-pressure features, are built into many gas spring models.

Precision: With gas springs, you can adjust the force applied for precise control of movement. This is particularly useful in applications like medical devices or machinery where precise adjustments are critical.

Ease of Use: Gas springs are simple to install and require no external power sources, making them a cost-effective and energy-efficient solution for many applications.

Compared to helical coil springs or other traditional springs, gas springs offer numerous advantages:

Longer Lifespan: Gas springs do not suffer from the same mechanical fatigue issues as traditional springs, meaning they last longer and require less maintenance.

Reduced Downtime: Gas springs improve productivity in industrial environments by reducing equipment downtime caused by spring failures.

More Versatile: With adjustable force settings and a variety of models, gas springs can be customized to fit a wide range of applications.

Choosing the right gas spring for your application depends on several factors:

Force: The required force is the most important consideration when selecting a gas spring. This depends on the weight or load that needs to be lifted or supported. The gas spring calculator can help you determine the right force based on your needs.

Stroke: The stroke is the maximum distance the piston moves from the fully compressed position to the fully extended position. You need to choose a gas spring with the appropriate stroke length to suit your application’s range of motion.

Mounting: Gas springs can be mounted in different orientations, including vertical, horizontal, and angled. Be sure to select the right orientation to ensure proper functionality and longevity of the spring.

Environment: Environmental conditions such as temperature, humidity, and exposure to chemicals can impact the performance of a gas spring. Choose a gas spring made from corrosion-resistant materials like stainless steel if your application is exposed to harsh conditions.

Durability: For heavy-duty applications, you may require heavy-duty gas springs that can handle high loads and extreme conditions without compromising performance.

Gas springs can be adjusted by modifying the internal gas pressure. This can be done by using pressure-adjustable gas struts, which allow you to fine-tune the force applied based on the needs of your application. The adjustment can be made using a valve or by selecting a gas spring with the appropriate pressure setting during the purchase process.

Gas springs are equipped with several safety features to prevent failure and protect both the system and personnel:

Over Stroke Active Safety (OSAS): This feature protects the gas spring from failure if the piston is extended beyond the maximum allowable stroke length. It allows for controlled depressurization during an overstroke, preventing catastrophic failure.

Uncontrolled Speed Active Safety (USAS): This mechanism ensures that if the gas spring experiences a shock load, the return stroke is controlled to prevent damage to the spring and injury to personnel.

Over Pressure Active Safety (OPAS): OPAS protects the gas spring and surrounding equipment from over-pressurization. If the pressure exceeds the rated limit, a rupture plug or exhaust groove releases the gas in a controlled manner, ensuring safe operation.

Gas springs ensure safe operation through a combination of passive safety features and controlled energy release. When a gas spring fails, it releases gas in a controlled manner rather than suddenly releasing all its energy, reducing the risk of accidents.

While gas springs are generally durable, they can occasionally fail. When this happens, they usually need to be replaced rather than repaired. However, if the spring is still under warranty, the manufacturer may offer replacement services.

The lifespan of a gas spring depends on the application and the frequency of use. On average, gas springs can last anywhere from 2,000 to 10,000 cycles. Regular maintenance, such as checking for leaks or corrosion, can help extend their lifespan.

Yes, gas springs can be customized to meet the exact requirements of a particular application. You can adjust the force, stroke length, and mounting options to create a gas spring that is perfectly suited to your needs.

In conclusion, gas springs are a versatile and essential component in many industries. They provide precise, controlled movement and offer numerous benefits, including durability, safety, and ease of use. Whether you're lifting heavy objects in the automotive industry, adjusting furniture components, or working with medical equipment, gas springs offer an efficient and reliable solution. By understanding their purpose, types, and how to choose the right gas spring, you can ensure smooth and safe operation in your applications.

For further information on selecting the right gas spring for your needs, contact an expert or use a gas spring calculator to find the best match for your application.